-

Industry News- Why is the Transfer Film Mechanism of a self lubricat...

Industry News- Why is the Transfer Film Mechanism of a self lubricat...In high-load and low-speed industrial applications, the transition toward maintenance-free components has prioritized the engineering of the...

-

Industry News- Can Switching to Self Lube Bearings Significantly Red...

Industry News- Can Switching to Self Lube Bearings Significantly Red...In the modern industrial landscape, the relentless pursuit of operational efficiency has led engineers to re-evaluate the most fundamental c...

-

Industry News- How Does a Bronze graphite bearing Maintain Consisten...

Industry News- How Does a Bronze graphite bearing Maintain Consisten...In heavy industrial applications where liquid lubricants vaporize or carbonize, the Bronze graphite bearing stands as a critical engineering...

-

Industry News- How to Accurately Calculate the Wear Life of a Self L...

Industry News- How to Accurately Calculate the Wear Life of a Self L...In the field of heavy-duty mechanical engineering, the reliability of a self lubrication bearing is critical for minimizing downtime and mai...

-

Industry News- How Do Self Lube Bearings Compare to Traditional Grea...

Industry News- How Do Self Lube Bearings Compare to Traditional Grea...In the demanding landscape of heavy industrial machinery, the choice between lubrication systems can dictate the entire lifecycle of a mecha...

-

0+Establishment

Founded in 2014, Shuangnuo has 10 years of experience in the industry.

-

0+Advanced Equipment

Strong production capacity ensures that we can organize material production for customers as soon as possible and shorten the production cycle.

-

0+Happy Clients

There are more than 5,000 cooperative customers around the world.

Improving Machinery Lifespan: Maintenance and Care Methods for SF-1 Oilless Bearings

Overview

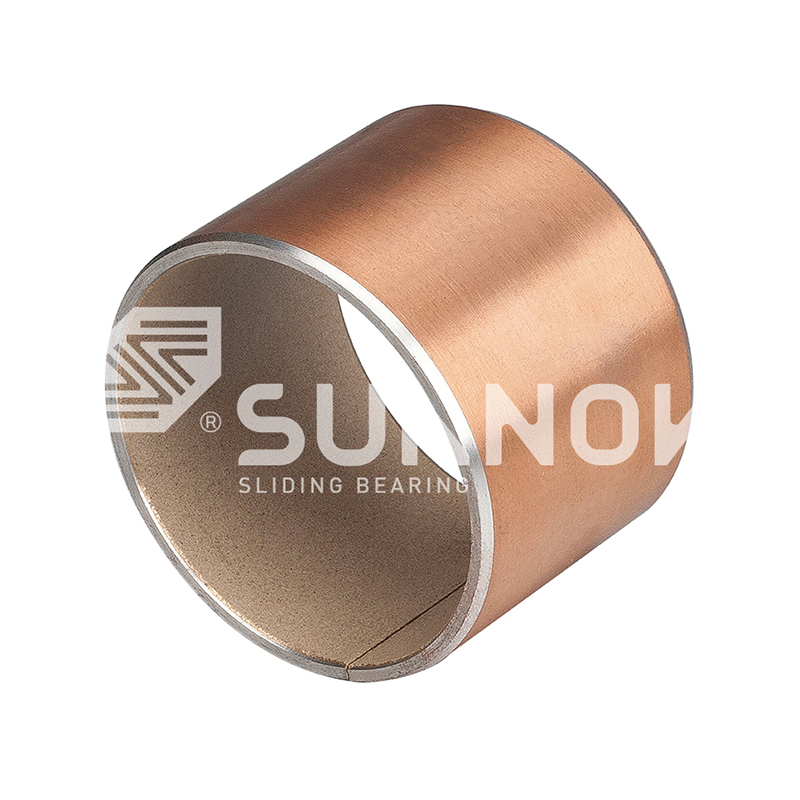

SF-1 Oilless Bearing is a self-lubricating, oil-free bearing widely used in industrial machinery, automotive, wind power equipment, and automated production lines. Its advantages include no need for additional lubrication, reduced maintenance costs, and excellent wear and corrosion resistance. To maximize machinery lifespan, proper maintenance and care are essential.

Company Background

Zhejiang Shuangnuo Bearing Technology Co., Ltd. specializes in manufacturing various self-lubricating copper alloy products, including brass, aluminum bronze, tin bronze, and more. The company also produces solid inlaid self-lubricating bearings and bimetallic products. Since its establishment nearly 10 years ago, Zhejiang Shuangnuo Bearing Technology has focused on independent raw material casting, full-process monitoring, and product testing to ensure quality. The company has over 80 advanced CNC machines, lathes, and machining centers, enabling full-process production from raw materials to finished products and providing personalized bearing design and customization based on customer requirements.

1. Features and Advantages of SF-1 Oilless Bearings

| Feature | SF-1 Oilless Bearing | Traditional Lubricated Bearing |

|---|---|---|

| Lubrication | Self-lubricating, no additional oil required | Requires regular oil or grease |

| Friction Coefficient | 0.08-0.12 (typical) | 0.15-0.25 |

| Temperature Range | -40℃ to +250℃ | -20℃ to +120℃ |

| Wear Resistance | High, long service life | Medium, faster wear |

| Maintenance Frequency | Low | High, requires regular maintenance |

| Application | Automation machinery, pumps, valves, wind power equipment | General mechanical equipment |

Note: Using SF-1 Oilless Bearings significantly reduces maintenance frequency and prevents lubrication-related failures.

2. Maintenance and Care Methods

2.1 Pre-Installation Inspection

- Dimension and Tolerance Check: Ensure the bearing bore, shaft diameter, and length match design parameters. Tolerances should comply with ISO or GB standards.

- Cleaning: The shaft, bore, and bearing must be free from dust, oil, and metal debris.

- Alignment Check: Avoid misalignment between shaft and bearing bore to prevent eccentric wear.

2.2 Care During Operation

- Avoid Overload: Maximum allowable load for SF-1 bearings is 25-35 MPa (typical for copper alloy). Long-term overload accelerates wear.

- Temperature Monitoring: Maintain operating temperature between -40℃ and 250℃. Exceeding this may damage the bearing.

- Dust and Contamination Protection: Avoid particles, dust, or chemicals entering the bearing surface.

2.3 Inspection and Replacement Cycle

- Operational Checks: Inspect bearing surface wear, axial clearance, and noise every 500-1000 operating hours.

- Wear Assessment: Replace the bearing if the inner diameter exceeds design tolerance, axial play increases, or abnormal noise occurs.

- Replacement Cycle: Under standard load, SF-1 bearings last 3-5 times longer than traditional lubricated copper bearings.

2.4 Cleaning and Recycling

- Surface Cleaning: Use a clean brush or compressed air to remove dust; avoid strong solvents.

- Recycling: Copper alloy SF-1 bearings can be melted and reused, meeting environmental standards.

3. Advantages Provided by Zhejiang Shuangnuo Bearing Technology Co., Ltd.

- Traceable Materials: Independent raw material casting with triple spectrometer checks before, during, and after furnace processing.

- Precision Machining: Over 80 advanced CNC machines ensure dimensional accuracy and tolerance compliance.

- Customized Solutions: Bearings designed according to machinery load, speed, and operating environment.

- Testing and Certification: Regular testing by national agencies for mechanical and chemical properties with official reports available.

Conclusion

By following proper installation, reasonable usage, and regular inspection practices, combined with high-quality SF-1 Oilless Bearings from Zhejiang Shuangnuo Bearing Technology Co., Ltd., machinery lifespan can be significantly extended, maintenance costs reduced, and operational reliability improved.