-

Industry News- Why is the Transfer Film Mechanism of a self lubricat...

Industry News- Why is the Transfer Film Mechanism of a self lubricat...In high-load and low-speed industrial applications, the transition toward maintenance-free components has prioritized the engineering of the...

-

Industry News- Can Switching to Self Lube Bearings Significantly Red...

Industry News- Can Switching to Self Lube Bearings Significantly Red...In the modern industrial landscape, the relentless pursuit of operational efficiency has led engineers to re-evaluate the most fundamental c...

-

Industry News- How Does a Bronze graphite bearing Maintain Consisten...

Industry News- How Does a Bronze graphite bearing Maintain Consisten...In heavy industrial applications where liquid lubricants vaporize or carbonize, the Bronze graphite bearing stands as a critical engineering...

-

Industry News- How to Accurately Calculate the Wear Life of a Self L...

Industry News- How to Accurately Calculate the Wear Life of a Self L...In the field of heavy-duty mechanical engineering, the reliability of a self lubrication bearing is critical for minimizing downtime and mai...

-

Industry News- How Do Self Lube Bearings Compare to Traditional Grea...

Industry News- How Do Self Lube Bearings Compare to Traditional Grea...In the demanding landscape of heavy industrial machinery, the choice between lubrication systems can dictate the entire lifecycle of a mecha...

-

0+Establishment

Founded in 2014, Shuangnuo has 10 years of experience in the industry.

-

0+Advanced Equipment

Strong production capacity ensures that we can organize material production for customers as soon as possible and shorten the production cycle.

-

0+Happy Clients

There are more than 5,000 cooperative customers around the world.

Strategies to Improve the Service Life of Self-Lubricating Copper Alloy Bearings

Introduction

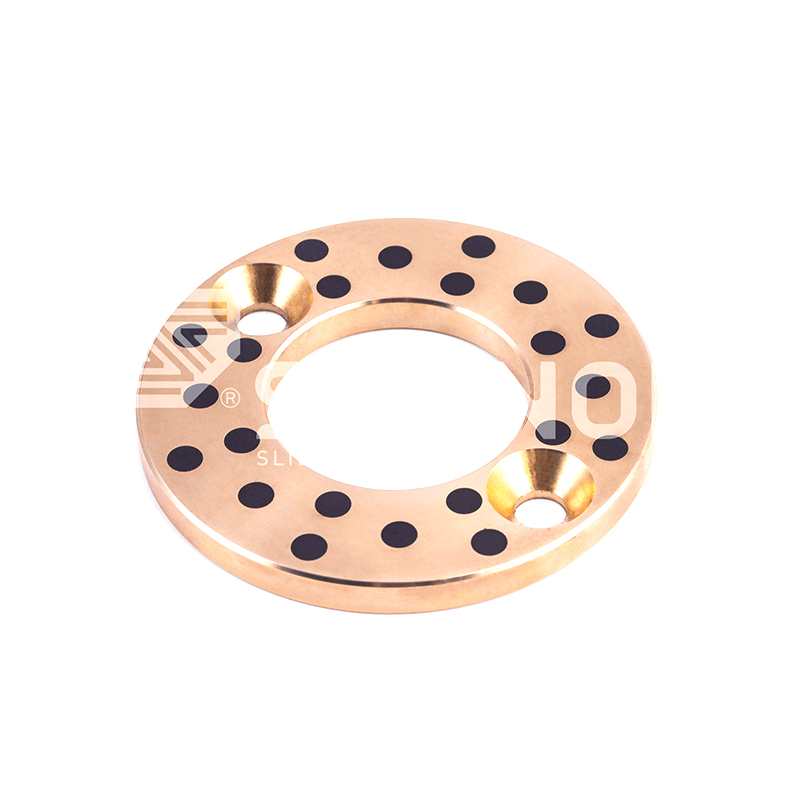

Self-lubricating copper alloy bearings are widely used in industrial machinery, automotive, and aerospace applications. Their service life is affected by multiple factors, including material, manufacturing process, design, and maintenance. Combining the technological advantages of Zhejiang Shuangnuo Bearing Technology Co., Ltd., the service life of bearings can be enhanced through the following strategies.

1. Material Selection and Optimization

Zhejiang Shuangnuo provides various copper alloy materials, including Brass, Aluminum Bronze, Tin Bronze, as well as solid self-lubricating inserts and bimetallic structures.

- Brass: Suitable for medium loads, moderate wear resistance, used as a baseline reference.

- Aluminum Bronze: High strength and wear resistance, suitable for heavy load and high-temperature applications.

- Tin Bronze: Excellent self-lubrication, suitable for low-speed or insufficient lubrication conditions.

- Self-lubricating inserts: Reduce friction coefficient, significantly extending bearing life.

- Bimetallic structures: Provide surface self-lubrication and base load support for overall performance enhancement.

2. Manufacturing Process and Quality Control

- Independent Casting: Zhejiang Shuangnuo insists on self-casting raw materials to ensure uniformity and stability.

- Casting Methods:

- Centrifugal Casting: High-precision round bearings

- Continuous Casting: Suitable for large-scale production

- Metal Mold Casting: High surface finish, reducing post-processing

- Full-Process Quality Control: Element composition is monitored with spectrometer before, during, and after melting; mechanical properties are regularly verified by national testing agencies.

- Machining Capability: Over 80 CNC machines, lathes, and machining centers. Surface roughness can reach Rz ≤ 0.8 μm, reducing friction and wear.

3. Design Optimization Strategies

- Clearance Design: Adjust bearing clearance based on load and speed to maintain complete lubrication film.

Speed Recommended Clearance Below 1000 rpm 0.03–0.05 mm 1000–3000 rpm 0.02–0.03 mm High load conditions Increase by 0.01–0.02 mm - Load Distribution Optimization: Use thick-wall or convex contact surfaces to improve bearing fatigue life.

- Lubrication Channel Design: Micro-channels can assist lubrication even in self-lubricating bearings, increasing service life by 15%-30%.

4. Installation and Maintenance Strategies

- Installation:

- Avoid dry friction at startup by applying a thin layer of grease on shaft or bearing surface

- Ensure coaxiality error ≤ 0.05 mm to prevent local wear

- Routine Maintenance:

- Regularly check operating temperature, vibration, and noise

- Supplement external lubricant under high temperature or heavy load conditions

- Replace bearings when wear exceeds 10%

- Environmental Protection: Prevent dust and debris from entering the bearing to avoid abrasive wear

5. Unique Advantages of Zhejiang Shuangnuo

- Customized Solutions: Tailored design based on customer conditions, including materials, structure, dimensions, and lubrication solutions.

- Short Production Cycle: Self-cast raw materials combined with CNC processing enable rapid delivery of high-precision bearings.

- Technical Reliability: 10 years of R&D experience, multiple quality checks, authoritative certification.

- Comprehensive Life Extension: By combining material selection, process optimization, design strategies, and maintenance, the overall bearing life can be extended by 30%-70%, significantly reducing downtime costs.

6. Life Improvement Comparison Table for Self-Lubricating Copper Alloy Bearings

| Category | Specific Strategy | Description | Expected Life Improvement |

|---|---|---|---|

| Material Selection | Brass | Medium load, moderate wear resistance | Baseline (1×) |

| Aluminum Bronze | High strength, wear-resistant, suitable for heavy load and high temperature | +30%-40% | |

| Tin Bronze | Excellent self-lubrication, suitable for low-speed or insufficient lubrication | +20%-30% | |

| Self-lubricating inserts | Reduce friction coefficient, improve wear resistance | +20%-50% | |

| Bimetallic structures | Surface lubrication, base load support | +25%-45% | |

| Manufacturing Process | Centrifugal Casting | High-precision bearings | +15%-25% |

| Continuous Casting | Large-scale production, reduced defects | +10%-20% | |

| Metal Mold Casting | High surface finish, reduces post-processing | +10%-15% | |

| CNC Precision Machining | Surface roughness Rz ≤ 0.8 μm | +10%-20% | |

| Design Optimization | Clearance Optimization | Prevent dry friction, maintain lubrication film | +10%-20% |

| Load Distribution Optimization | Thick-wall/convex design enhances load support | +15%-25% | |

| Lubrication Channel Design | Assists lubrication, extends life | +15%-30% | |

| Installation & Maintenance | Precision Installation | Coaxiality error ≤ 0.05 mm | +5%-10% |

| Routine Checks & Lubrication | Prevent overheating and wear | +10%-15% | |

| Dust Protection | Reduce abrasive wear | +5%-10% | |

| Comprehensive Strategy | Material + Process + Design + Maintenance | Zhejiang Shuangnuo Customized Solution | +30%-70% |