-

Industry News- Why is the Transfer Film Mechanism of a self lubricat...

Industry News- Why is the Transfer Film Mechanism of a self lubricat...In high-load and low-speed industrial applications, the transition toward maintenance-free components has prioritized the engineering of the...

-

Industry News- Can Switching to Self Lube Bearings Significantly Red...

Industry News- Can Switching to Self Lube Bearings Significantly Red...In the modern industrial landscape, the relentless pursuit of operational efficiency has led engineers to re-evaluate the most fundamental c...

-

Industry News- How Does a Bronze graphite bearing Maintain Consisten...

Industry News- How Does a Bronze graphite bearing Maintain Consisten...In heavy industrial applications where liquid lubricants vaporize or carbonize, the Bronze graphite bearing stands as a critical engineering...

-

Industry News- How to Accurately Calculate the Wear Life of a Self L...

Industry News- How to Accurately Calculate the Wear Life of a Self L...In the field of heavy-duty mechanical engineering, the reliability of a self lubrication bearing is critical for minimizing downtime and mai...

-

Industry News- How Do Self Lube Bearings Compare to Traditional Grea...

Industry News- How Do Self Lube Bearings Compare to Traditional Grea...In the demanding landscape of heavy industrial machinery, the choice between lubrication systems can dictate the entire lifecycle of a mecha...

-

0+Establishment

Founded in 2014, Shuangnuo has 10 years of experience in the industry.

-

0+Advanced Equipment

Strong production capacity ensures that we can organize material production for customers as soon as possible and shorten the production cycle.

-

0+Happy Clients

There are more than 5,000 cooperative customers around the world.

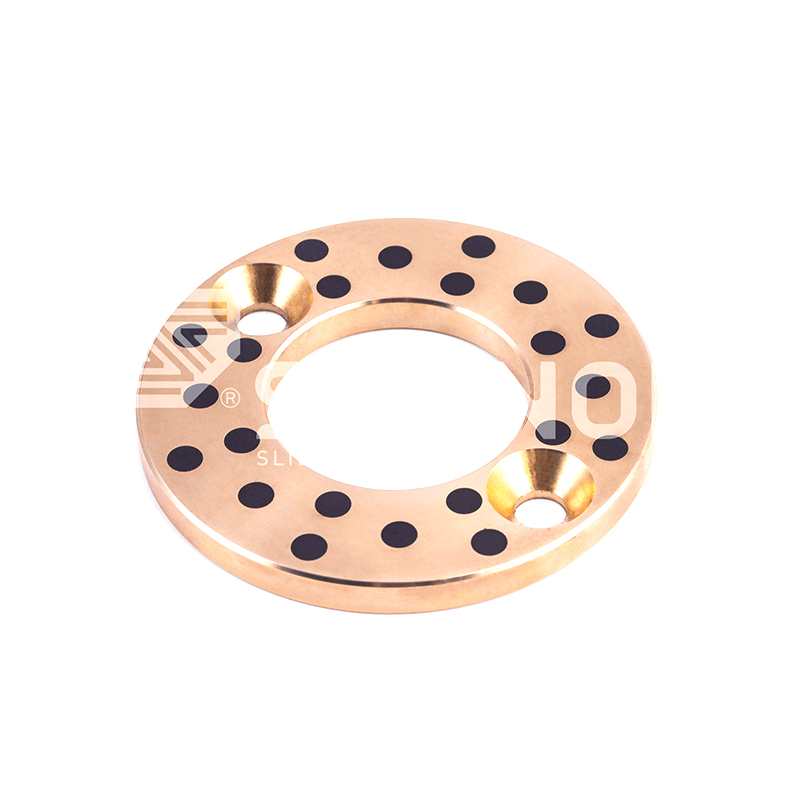

Analysis of the Working Principle and Material Properties of JDB Solid-Lubricating Bearings

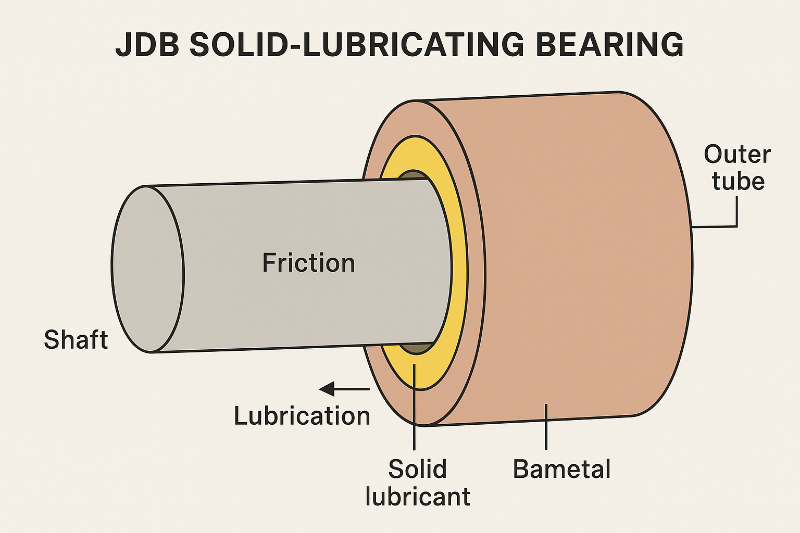

1. Working Principle

JDB solid-lubricating bearings are a type of self-lubricating bearing. Their core principle is to embed solid lubricants within the bearing material to achieve lubrication, reducing friction and wear. Unlike traditional grease lubrication, solid-lubricating bearings can maintain a stable coefficient of friction in dry or high-temperature environments.

Main Features:

- Self-lubrication: Solid lubricants form a thin lubricating film on the bearing surface, continuously reducing friction.

- High-temperature resistance: Suitable for high-temperature applications without the risk of lubricant failure.

- Low maintenance: No need to regularly add or replace lubricants, reducing downtime and maintenance costs.

- Wide applicability: Can be used in metallurgy, machinery manufacturing, mining equipment, shipbuilding, and other industries.

2. Material Properties

Zhejiang Shuangnuo Bearing Technology Co., Ltd. specializes in the development and production of various self-lubricating copper alloy products. The solid-lubricating bearings typically have the following characteristics:

| Material Type | Manufacturing Process | Properties | Application Advantages |

|---|---|---|---|

| Brass | Centrifugal casting, continuous casting, metal mold casting | Good thermal conductivity, easy machining, corrosion-resistant | Low to medium load bearings, light machinery |

| Aluminum Bronze | Centrifugal casting, continuous casting | High strength, good wear resistance, corrosion-resistant | High load, impact load bearings |

| Tin Bronze | Centrifugal casting, continuous casting | Strong wear resistance, low friction coefficient | Long-life bearing applications |

| Bimetal | Sintering technology | Metal substrate + self-lubricating layer, combines strength and lubrication performance | High-speed, high-load, special operating conditions |

Material Advantages:

- Independent casting of raw materials: Ensures uniformity and stability of material properties.

- Strict quality control: Each batch is tested three times with a spectrometer during pre-furnace, in-furnace, and post-furnace stages. National testing agencies are regularly commissioned for material composition and mechanical property verification.

- Advanced machining equipment: Over 80 CNC machines, lathes, and machining centers enable high-precision bearing processing.

- Customizable design: Tailored solutions based on customer product and application requirements ensure optimal performance.

3. Parameter Comparison Example

| Parameter | Brass Self-Lubricating Bearing | Aluminum Bronze Self-Lubricating Bearing | Tin Bronze Self-Lubricating Bearing | Bimetal Bearing |

|---|---|---|---|---|

| Allowable Load (MPa) | 50-80 | 100-150 | 80-120 | 120-200 |

| Friction Coefficient μ | 0.05-0.12 | 0.04-0.10 | 0.03-0.08 | 0.03-0.06 |

| Operating Temperature (°C) | -50 ~ 150 | -50 ~ 300 | -50 ~ 200 | -50 ~ 350 |

| Corrosion Resistance | Medium | High | High | High |

| Service Life | Medium | High | High | Very High |

4. Conclusion

JDB solid-lubricating bearings achieve self-lubrication through embedded solid lubricants. Combined with the advanced casting and machining processes of Zhejiang Shuangnuo Bearing Technology Co., Ltd., these bearings maintain stable performance under high load, high temperature, and complex operating conditions. Strict raw material and production controls ensure excellent wear resistance, low friction coefficient, and long service life. Custom design solutions further allow bearings to perfectly match customer applications, making Zhejiang Shuangnuo a leading company in the domestic self-lubricating bearing industry.