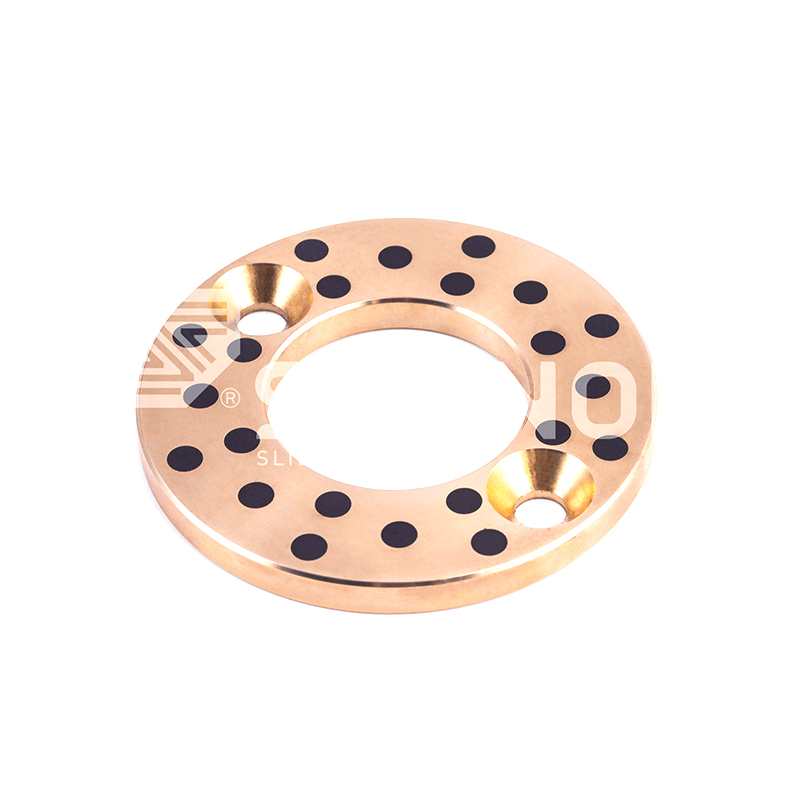

Engineered for unparalleled performance in demanding applications, the FZ Steel Ball Retainer is a high-precision component designed to enhance the reliability and longevity of linear motion systems. This bearing cage provides superior alignment and uniform load distribution, critical for preventing premature wear in high-speed and high-load environments. Our retainers are the preferred choice for engineers and purchasing managers seeking durable, high-performance solutions for industrial machinery.

Product Features

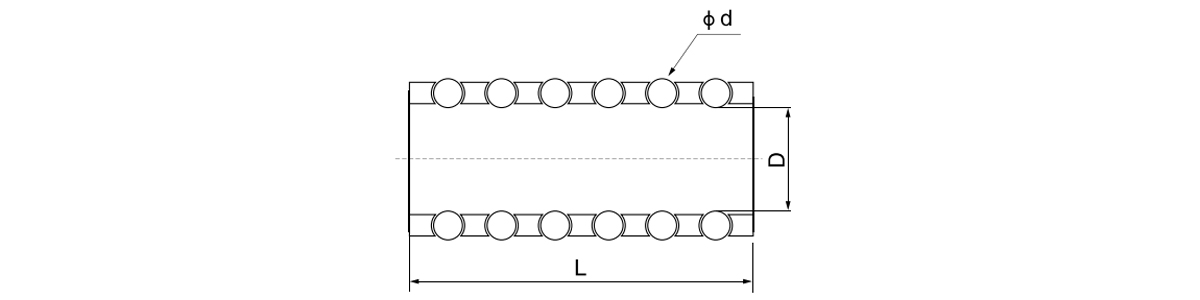

- Precision-Formed Steel Construction: Manufactured from high-grade steel, the FZ retainer ensures exceptional rigidity and dimensional stability. This design minimizes friction and vibration, resulting in smoother operation and extended service life for linear guides and shafts.

- Optimized Ball Pocket Geometry: Each ball pocket is precision-machined to hold and guide steel balls with minimal clearance. This feature facilitates smooth ball circulation, crucial for maintaining consistent motion and preventing binding under heavy dynamic loads.

- Enhanced Lubrication Channels: The retainer's design incorporates internal channels that facilitate efficient lubricant distribution to all rolling elements. This ensures optimal lubrication, reducing heat generation and resistance, which is vital for high-speed linear motion applications.

- Corrosion-Resistant Finish: A specialized surface treatment provides robust protection against rust and corrosion, making the FZ steel ball retainer suitable for use in harsh industrial environments, including those with exposure to moisture or chemicals.

Applications

The FZ Steel Ball Retainer is an essential component for high-precision and heavy-duty industrial machinery. Its robust design and reliable performance make it ideal for:

- CNC machine tools and linear actuators

- Automated manufacturing and assembly lines

- Robotics and material handling equipment

- Heavy-duty presses and stamping machinery

- Medical and laboratory equipment requiring precise linear movement

Common Purchasing Inquiries

1. How does the FZ Steel Ball Retainer compare to bronze or polymer bearing cages in terms of load capacity and durability?

The FZ steel ball retainer significantly outperforms bronze or polymer cages in high-load and high-shock applications. Its high-carbon steel construction provides superior rigidity, preventing deformation under extreme stress and ensuring consistent ball alignment. This results in a higher dynamic load rating and a longer service life, making it a more cost-effective choice for heavy-duty industrial machinery. For a detailed analysis of your specific application requirements, please consult with our engineering team.

2. We are experiencing premature bearing failure due to insufficient lubrication in our high-speed linear guide. Can your product solve this issue?

Premature failure often stems from inadequate lubrication and excessive heat generation. The FZ Steel Ball Retainer is specifically engineered with optimized internal lubrication channels that ensure uniform distribution of grease or oil to every rolling element. This design minimizes friction and heat buildup, crucial for extending the life of high-speed linear motion systems. Our retainer's robust structure also maintains alignment under demanding conditions, a key factor in preventing uneven wear. To ensure a correct fit and optimal performance, we recommend a technical review of your existing system.