Product Features

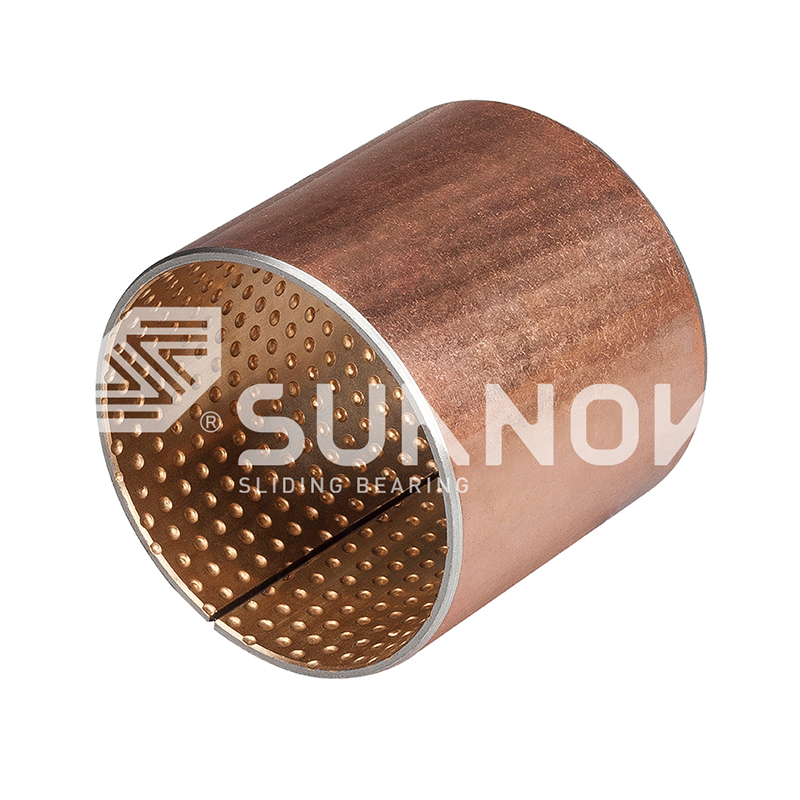

- Advanced Material Composition: The FB08G bearing is engineered from a high-quality steel substrate bonded with a wear-resistant bronze powder layer, then infused with a solid lubricant mixture of steel and graphite. This design ensures exceptional performance and longevity.

- Self-Lubricating Operation: The solid lubricant provides continuous lubrication throughout the bearing's service life, eliminating the need for external oil or grease. This characteristic makes the bearing ideal for applications where maintenance is difficult or undesirable, such as in conveyor systems and heavy machinery.

- Superior Wear and Corrosion Resistance: The steel and graphite blend significantly enhances the bearing's resistance to abrasion and corrosion, extending its operational life even in harsh industrial environments.

- High Load Capacity: Designed to withstand heavy radial and axial loads, the FB08G bearing is suitable for demanding applications in the construction, automotive, and agricultural industries.

- Oil-Free and Environmentally Friendly: The self-lubricating nature of the bearing reduces environmental impact by eliminating the risk of oil spills and contamination. It is an excellent choice for applications requiring clean operation, such as in food processing equipment.

Product Description

The FB08G Steel+Graphite Wrapped Bearing is a high-performance sliding bearing designed to meet the rigorous demands of modern industrial applications. Its unique composite structure combines the strength of steel with the self-lubricating properties of graphite and bronze, offering a robust solution for dry operation. This bearing is meticulously manufactured to strict quality standards, providing reliable, maintenance-free performance and a long service life.

This product is an effective solution for engineers and procurement managers seeking a durable, lubrication-free bearing for applications involving medium to high loads and intermittent motion. It addresses key challenges such as lubrication failure, maintenance costs, and environmental compliance in sectors including construction, material handling, and automotive systems.

Application Areas

This product is a strategic choice for industrial applications requiring a lubrication-free and durable solution, including:

- Agricultural Machinery (tractors, harvesters)

- Construction Equipment (excavators, loaders)

- Material Handling Systems (conveyors, lifts)

- Hydraulic Machinery (pumps, valves)

- General Industrial Machinery

Common Purchasing Inquiries

1. How does the FB08G bearing compare to a standard bronze bushing for a high-load, intermittent motion application?

While standard bronze bushings require external lubrication to function effectively, the FB08G bearing is designed for dry operation. Its self-lubricating properties prevent wear and premature failure in intermittent motion scenarios where traditional lubrication may be squeezed out. This not only reduces maintenance but also ensures consistent performance under varying load conditions. For a detailed comparison based on your specific load and speed requirements, please contact our technical team for a free application analysis.

2. What is the expected service life of the FB08G bearing in a dusty, outdoor environment, and how can I verify its durability?

The service life of the FB08G bearing is significantly extended in dusty environments due to its wear-resistant steel and graphite composite structure, which is less susceptible to abrasive particles than a traditional lubricated bearing. The solid lubricant is embedded within the bearing material, preventing external contaminants from compromising its function. We recommend conducting a pilot test under your specific operating conditions. Our engineers can provide sample bearings and technical support to help you evaluate performance and durability firsthand.